Peb txhua tus paub tias nyob rau hauv kev tsim cov txhuas profiles, cov nyiaj tau los = kev muag khoom rho tawm cov nqi ntau lawm.Cov nqi tag nrho ntawm txhuas profile yog muab faib ua cov nqi ruaj khov thiab cov nqi sib txawv.Txhim cov nqi xws li cog cov nqi xauj tsev, kev txo nqi ntawm cov tshuab, thiab lwm yam.Nws yog ruaj. cov nqi sib txawv muaj ntau qhov yooj.

Nyob rau hauv cov ntaub ntawv ntawm tib lub txhuas profile muag nqi, tus nqi siab dua ntawm aluminium profile, qhov nyiaj tsawg dua.Tam sim no, nyob rau hauv ib puag ncig hnyav ntawm cov khoom siv raw khoom, nce cov neeg ua haujlwm cov nyiaj ua haujlwm, kev txaus siab ntawm RMB, nce nqi zog, nce nqi se thiab lwm yam, kev sib tw hauv tib lub lag luam tau nkag mus rau "dawb-kub" niaj hnub no.Lub sijhawm tau los rau kev tswj tus nqi zoo.

Kev tswj tus nqi yog qhov tseem ceeb uas lub tuam txhab tswj hwm thiab cov tub ntxhais.Tsuas yog los ntawm tas li nrhiav qhov txuas tsis muaj zog, mining muaj peev xwm sab hauv, tuaj yeem siv txhua txoj hauv kev los txo cov nqi, kev koom tes tag nrho, pib los ntawm cov ntsiab lus, pib los ntawm kev txo cov khib nyiab, txhuas. zoo rau kev siv cov nqi tswj, tuaj yeem nthuav dav qhov chaw ntawm kev lag luam muaj sia nyob, txhim kho kev tswj hwm kev lag luam, ua kom lub lag luam ruaj khov, thiab nyob rau hauv txoj hauj lwm impregnable.

Aluminium profile tus nqi tswj yog nyob ntawm tus nqi saw raws li cov lus qhia, tus nqi tswj tau muab faib ua tus nqi tsim, tus nqi yuav khoom, tus nqi tsim khoom, tus nqi muag khoom thiab kev pabcuam tus nqi.Vim tias tus nqi tswj muaj ntau qhov chaw, cov ntsiab lus ntau.Kuv yuav tham. hais txog yuav ua li cas txhim kho tus nqi ntawm cov khoom tiav los ntawm qhov pom ntawm kev tsim khoom kom txo tau cov nqi tsim khoom.

Los ntawm kev txheeb xyuas cov ntaub ntawv thiab kev xyaum, nws tau raug pov thawj tias kev txhim kho cov txiaj ntsig ntawm aluminium alloy profiles yog ib txoj hauv kev ncaj qha thiab siv tau los txo cov nqi tsim khoom.Noj cov extrusion Rhiav ua piv txwv, cov nqi tsim khoom ntawm txhuas cov ntaub ntawv yuav raug txo los ntawm 25-30 yuan ib tuj yog tias cov txiaj ntsig tau nce los ntawm ib feem pua, thiab qhov txo qis yog cov nyiaj tau los ntawm kev lag luam. yield, lub luag haujlwm ntawm ntau lawm yog los txo cov extrusion pov tseg.

Yuav ua li cas txhawm rau txhim kho cov txiaj ntsig ntawm aluminium profiles kom txo tau cov khoom pov tseg aluminium, txhim kho cov khoom tsim tau, thiab txo cov nqi tsim khoom ntawm aluminium profiles, peb tau sau cov ntaub ntawv extruded khib nyiab:

Cov khib nyiab ntawm aluminium extruded profiles tuaj yeem muab faib ua ob pawg: geometric pov tseg thiab kev pov tseg.Geometric pov tseg yog ib qho khoom pov tseg uas tsis muaj kev cuam tshuam ntawm aluminium alloy profiles thaum extrusion.xws li extrusion ntawm cov khoom seem, ncab cov khoom ntawm ob kawg ntawm chuck, qhov loj ntawm cov khoom siv tsis txaus qhov ntev ntawm qhov ntev ntawm cov khoom tso tseg, txiav cov qauv tsim nyog, shunt ua ke tuag nyob rau hauv lub shunt chamber ntawm cov seem txhuas thaiv, ingots thiab cov khoom txiav qhov loj ntawm cov khoom ntawm saw-hluav taws xob. noj ntawm txhuas chips thiab txhuas ingots noj thaum lub sij hawm pwm kuaj.

Kev pov tseg yog cov khoom pov tseg uas tsim los ntawm cov cuab yeej siv tsis tsim nyog, cov khoom siv teeb meem thiab kev ua haujlwm tsis raug ntawm cov neeg ua haujlwm hauv cov txheej txheem ntawm aluminium alloy profile ntau lawm.Tshwj xeeb ntawm cov khoom pov tseg geometrical, nws tuaj yeem kov yeej thiab tshem tawm cov tiam ntawm cov khoom pov tseg los ntawm kev txhim kho thiab kev tswj kom muaj zog. .Technical pov tseg tuaj yeem muab faib ua:

Cov khoom pov tseg cov ntaub so ntswg: overburning, coarse grain nplhaib, coarse grain, tail shrinkage, slag inclusion, thiab lwm yam.

Cov cuab yeej cuab tam tsis tsim nyog pov tseg: lub zog, hardness tsawg dhau, tsis ua raws li lub teb chaws tus qauv;los yog yas yog tsawg dhau, tsis txaus softening tsis tau raws li cov kev cai.

Cov khoom pov tseg saum npoo: txheej, npuas, extrusion tawg, txiv kab ntxwv tev, cov ntaub so ntswg clauses, dub me ntsis, longitudinal vuam kab, transverse vuam kab, khawb, hlau nias, thiab lwm yam.

Geometric dimension pov tseg cov khoom: yoj, twist, khoov, dav hlau clearance, loj tawm ntawm kam rau ua, thiab lwm yam.

Tus nqi ntawm cov khoom tiav kev faib cov neeg ua haujlwm raws li tus nqi ntawm cov khoom tiav thiab cov txiaj ntsig zoo.

Cov txheej txheem tiav aluminium feem ntau yog hais txog cov txheej txheem tseem ceeb, feem ntau yog ua raws li kev cob qhia ua chav tsev rau kev suav.Casting txheej txheem (casting Rhiav), extrusion txheej txheem (extrusion txheej txheem), oxidation coloring txheej txheem (oxidation rhiav), hmoov txau txheej txheem (txhaj tshuaj rhiav. ).Nws yog txhais raws li qhov piv ntawm cov khoom tsim nyog ntawm lub rooj cob qhia rau cov tswv yim ntawm cov khoom siv raw (lossis cov khoom tiav ib nrab) hauv kev cob qhia.

Tus nqi ntawm cov khoom tiav yog muaj feem xyuam rau cov khoom zoo, ingot zoo, cov qauv khoom, zaus ntawm kev hloov ntawm ntau yam thiab specifications, advanced degree ntawm technology, enterprise tswj theem thiab zoo ntawm cov tswv thiab lwm yam.

Tus yuam sij los txhim kho cov txiaj ntsig ntawm aluminium alloy profiles yog txo thiab tshem tawm cov khoom pov tseg.Geometric pov tseg yog qhov tsis tuaj yeem zam tau, tab sis nws tuaj yeem txo qis.Technical pov tseg yog tib neeg qhov tseem ceeb, uas tuaj yeem tshem tawm ntawm rooj plaub los yog txo qis. .Yog li ntawd, kev tswj tau zoo thiab kev txhim kho cov txiaj ntsig ntawm cov khoom extruded tuaj yeem txais yuav.

Txo geometric pov tseg yog qhov tseem ceeb ua ntej txhawm rau txhim kho cov txiaj ntsig ntawm cov khoom tiav

Kev ntsuas los txo cov khib nyiab geometric

Kev xaiv kom raug ntawm ingot ntev yog lub ntsiab ntsuas los txo cov txheej txheem pov tseg.Qhov ntev ntawm lub ingot yog tsis xam tom qab extrusion, tab sis xam tom qab extrusion.

Tam sim no feem ntau cov tuam txhab siv cov pas nrig ntev kub shear aluminium pas nrig cua sov rauv, piv nrog luv luv pas nrig cua sov rauv, txo qhov poob ntawm txhuas chips, vim yog kev hloov ntawm pwm phab ntsa thickness, lub casting ntev tswj yog ntau saj zawg zog thiab yog, zoo heev txhim kho. cov yield.Tab sis ntau lub lag luam nyob rau hauv kev siv cov pas nrig ntev kub shear rauv, tsis quav ntsej qhov kev suav ntawm casting ntev, thiab ncaj qha xa mus rau tus neeg teb xov tooj los tswj.Thiab tus neeg teb xov tooj yog feem ntau raws li kev paub nyob rau hauv thawj bar, soj ntsuam cov qhov ntev ntawm cov khoom siv, yog tias qhov sib txawv loj, txuas ntxiv kho, feem ntau xav tau txog 3 tuav kom tau qhov tseeb ntev.Nyob rau hauv cov txheej txheem, ntau cov khoom pov tseg tau tsim, uas txo cov kev tsim khoom thiab kev tawm los.

Txoj hauv kev kom raug yog tias qhov ntev ntawm lub ingot yog xam los ntawm cov txheej txheem tswj xyuas thaum pib ntawm cov pwm.Thaum cov pwm tsim tawm ntawm lub tshuab rau ntau zaus, qhov ntev ntawm tus pas nrig sau rau ntawm daim npav pwm yog nce me ntsis los ntawm 5-10mm, thiab qhov ntev ntawm cov khoom raug soj ntsuam thaum cov khoom tsim.Fine tuning yog tias muaj. Qhov sib txawv.Yog li tus pas nrig thib ob yog qhov tseeb heev.Raws li qee cov ntaub ntawv, cov txiaj ntsig ntawm cov khoom tiav tuaj yeem nce ntxiv los ntawm 4 feem pua cov ntsiab lus los ntawm kev siv cov kub kub ntev ntev, thiab nws muaj peev xwm ua kom tiav cov txiaj ntsig los ntawm 2 mus rau 3 feem pua cov ntsiab lus hauv qhov tseeb. ntau lawm.

Tsis tas li ntawd, tus naj npawb ntawm cov khoom ntev ntev los yog cov khoom ntev, txhawm rau kom ntseeg tau tias qhov kev ua haujlwm du extrusion nyob rau hauv qhov chaw ntawm extrusion.Thaum qhov ntev ntawm lub txaj txias yog ntev txaus, nce qhov ntev ntawm qhov ruaj khov lossis qhov ntev ntawm cov khoom. ntau npaum li qhov ua tau, uas yog, qhov ntev ingot tuaj yeem raug xaiv.Nws kuj yog ib txoj hauv kev zoo los txo cov feem pua ntawm cov khib nyiab geometric thiab nce cov txiaj ntsig ntawm cov khoom tiav.

Kev ntsuas los txhim kho tus nqi ntawm cov khoom tiav los ntawm qib kev

Nws yog ib qho tseem ceeb kev ntsuas los txhim kho tus nqi ntawm cov khoom tiav los txhim kho qib pwm tsim thiab tsim thiab txo Lub Sijhawm ntawm pwm kuaj. Feem ntau tsis yog qhov kev sim pwm no raug nqi 1-3 ingots, kom cov qoob loo txo 0.5-1. %, vim yog cov pwm tsim, qib tsim qis, qee yam khoom kho pwm, pwm 3-4 zaug lossis ntau lub sijhawm los tsim cov khoom tiav, immaterially txo cov txiaj ntsig ntawm 2-5%, uas yuav tsis tsuas yog ua rau kev lag luam. poob, tab sis kuj yog vim rov kuaj pwm, yuav txuas ntxiv lub voj voog ntau lawm.

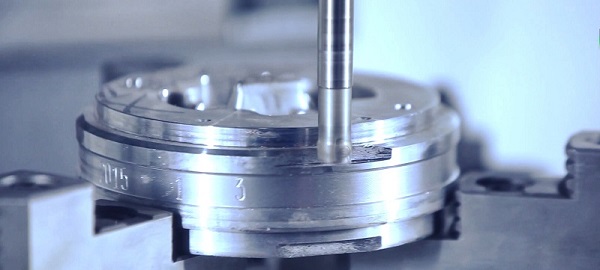

Niaj hnub nimno pwm xoom kuaj lub tswv yim, uas yog, tom qab pwm tsim, tsis tas yuav kuaj pwm, koj tuaj yeem ncaj qha rau ntawm lub tshuab los tsim cov khoom tsim nyog.Siv simulation tsim software, finite element tsom xam, tsim tuaj yeem ua tiav hauv computer.Nws tseem tuaj yeem raug kuaj los ntawm lub computer simulation.Pwm kab noj hniav ua tiav hauv qhov chaw machining tsis siv neeg, kev ua haujlwm ntawm tag nrho cov pwm yog siab precision, yog li qhov zoo ntawm pwm yog siab heev.Ntawm lub tshuab hla tus nqi ntau tshaj. 90% Nws tuaj yeem nce cov txiaj ntsig ntawm cov khoom tiav los ntawm 2-6%.

Tsim nyog ua kom cov extrusion coefficient ntawm aluminium los txhim kho cov khoom lag luam

Txhua lub Hoobkas aluminium muaj cov tshuab ntau lawm, txhua lub Hoobkas raws li qhov sib piv ntawm cov khoom siv, qhov ntev ntawm lub txaj txias, qhov seem ntawm cov khoom, qhov ntev ntawm lub tog raj kheej extrusion, los txiav txim cov khoom ntawm lub tshuab sib txuas production.Practice tau ua pov thawj tias tib yam specifications ntawm cov khoom, muab tso rau hauv txawv tonnage extrusion tshuab ntau lawm, vim hais tias ntawm qhov sib txawv extrusion coefficient, cov qauv ntawm cov khoom ua tau zoo thiab ntau lawm efficiency muaj ib tug zoo heev cuam tshuam, nws yield yuav kuj tsim txawv.Thaum lub extrusion tshuab tonnage loj dua, cov extrusion coefficient loj dua, cov khoom tiav cov nqi siab dua, thiab tus nqi extrusion yog ze rau.

Txhim kho qhov zoo ntawm ingot yog lub hauv paus ntawm kev txhim kho cov yield

Ingots yog cov khoom siv raw ntawm kev tsim khoom extrusion.Ingots muaj cov qauv zoo, cov nplej zoo, tsis muaj slag, pores, cais, tawg thiab lwm yam tsis xws luag, uas tuaj yeem tsis tsuas yog txo cov extrusion siab, txhim kho cov extrusion ceev, thiab txhim kho cov khoom zoo sab hauv.Thiab tuaj yeem txo cov khoom npuas npuas, pores, khawb, tawg, pitting thiab lwm yam tsis xws luag.Smaller slag inclusion yuav raug tso tawm los ntawm lub slit ntawm pwm ua hauj lwm txoj siv, tab sis nws yuav ua rau pears nyob rau hauv profile nto, uas ua rau ib tug tej yam ntev ntawm pov tseg.Qhov loj slag suav nrog yuav yuav daig nyob rau hauv lub slit ntawm txoj siv sia ua haujlwm thiab tsis tuaj yeem raug tshem tawm, uas yuav ua rau cov pwm ntsaws lossis cov khoom tawg thiab hloov cov pwm, uas yuav cuam tshuam rau kev tawm los.Siv cov ntaub qhwv sib xws thaum ncab thiab ncaj los txo qhov ntev ntawm lub taub hau thiab tus Tsov tus tw. khoom.

Profile nyob rau hauv stretch straightening, ntau lub lag luam tsis tsim lub cushion sib xws, tshwj xeeb tshaj yog ib co loj dai profile thiab hollow profile.Vim li ntawd, lub deformation ntawm lub taub hau thiab tus Tsov tus tw ntawm lub profile yog loj heev, thiab lub deformation ib feem yuav tsum raug txiav tawm thaum sawing cov khoom tiav.Qhov no tau ua rau poob ntawm tus nqi ntawm cov khoom tiav.

Lub cushion tuaj yeem ua los ntawm hardwood lossis aluminium blocks.Tus tsim minimizes qhov loj ntawm lub cushion thiab nce nws versatility.Rau qhov ntev phab ntsa thiab kaw seem ntawm cov profile, straightening nyob rau hauv lub kaw kab noj hniav rau hauv ncoo tab sis kuj muab cov kev txhawb nqa ncej nyob rau hauv ib feem ntawm lub phab ntsa. Yog li, lub deformation nyob rau hauv qhov ntev ntawm kev taw qhia yog txo.Fixtures yuav tsum tau tsim, tswj thiab coj los ntawm cov neeg ua haujlwm tshwj xeeb.

Nyob rau tib lub sijhawm, txhawm rau tiv thaiv qhov tshwm sim uas cov neeg ua haujlwm tsis kam siv lub cushion vim tias muaj teeb meem, peb yuav tsum tsim kom muaj qhov khoom plig thiab kev rau txim uas tus nqi ntawm cov khoom tiav yog txuas nrog cov nyiaj ua haujlwm.

Txhim khu kev tswj ntawm extrusion tuag thiab thawj cov ntaub ntawv tsim tawm ntawm aluminium profile.

Daim npav pwm thiab cov ntaub ntawv tsim khoom qub tseem ceeb heev.Daim npav pwm yuav tsum muaj peev xwm qhia tau qhov teeb meem ntawm nitriding ntawm pwm, kev saib xyuas qhov xwm txheej thiab cov khoom siv.Cov ntaub ntawv tseem ceeb yuav tsum muaj peev xwm qhia tau tiag tiag tias qhov kev txhawb nqa hnyav, qhov ntev thiab qhov ntau muab lub hauv paus txhim khu kev qha rau kev tsim khoom tom ntej.

Tam sim no ntau lub lag luam kuj tau paub txog kev tswj xyuas cov ntaub ntawv hauv computer, tab sis tseem muaj txoj hauv kev ntev mus rau kev siv tiag tiag.

Txo geometrical pov tseg los ntawm kev siv xovxwm-dawb tom qab extrusion

Lub ncoo ruaj ruaj yog tsau rau ntawm tus pas nrig extrusion yam tsis muaj qhov seem extrusion, thiab ob qho tib si raug hloov kho rau ib qho twg.Thaum lub tog raj kheej extrusion tsis thim rov qab, lub siab ncoo kuj tseem yooj yim cais tawm ntawm lub ingot.Cov ingot tom ntej no ces thawb ncaj qha. Nyob rau hauv lub extrusion cartridge.Extruded nrog cov seem ntawm yav dhau los ingot, yog li zam qhov yuav tsum tau shear txhua ingot ib zaug.Raws li qhov yuav tsum tau zoo thiab txiav txim kom muaj nuj nqis los txiav txim tus naj npawb ntawm casting shear xovxwm.Feem ntau 40-50 daim yog txiav ntawm ib sij hawm.

Txhim kho cov txheej txheem extrusion ntawm aluminium profiles kom txo tau cov khoom pov tseg

Muaj ntau yam cuam tshuam rau cov txheej txheem extrusion ntawm kev pov tseg, uas npog tag nrho cov txheej txheem extrusion ntau lawm.Mainly muaj xws li: ingot zoo, txheej txheem kub, extrusion ceev, extrusion cuab yeej, tuag, hloov chaw thau khoom thiab unloading, laus kho, thiab lwm yam. txoj kev loj hlob ntawm advanced, scientific ntau lawm technology, tab sis kuj yog qhov tseeb nruj kev siv ntawm cov txheej txheem kev khiav hauj lwm, txhim kho cov neeg ua hauj lwm kev txawj ntse thiab kev nkag siab ntawm lub luag hauj lwm.

Raws li qhov ua tau kom txo tau ntau yam kev tsim tawm ib qho kev ua haujlwm, nws yog qhov zoo tshaj plaws los npaj tsuas yog 3-5 ntau yam ntawm ib qho kev ua haujlwm, txhawm rau txhim kho qhov tsim ntawm ib txheej ntawm pwm.Qhov ntau yam ntawm lub tshuab, ntau pwm txhuas yuav yog. tshem tawm, qhov qis dua qhov tawm los.

Cov nyhuv ntawm pwm ntawm qhov tawm los yog tsuas yog nyob rau hauv ob yam: tshiab pwm kuaj thiab siv cov pwm ntau lawm

Lub sij hawm ntau lub pwm raug sim, qhov ntau aluminium pwm raug tshem tawm, thiab qhov qis dua qhov tawm los.Yog li peb yuav tsum txhim kho tus qauv tsim thiab qib ntawm cov pwm.

Pwm ntau lawm yuav tsum tau ua tib zoo tswj xyuas, tsim nyog nitriding, tu raws sij hawm.Ua kom txhua lub sij hawm ntawm lub tshuab tsim nyog tus nqi yog siab.zoo molding thiab siab durability.Yog hais tias txhua yam hloov vim pwm txij nkawm tsis tsim nyog, ua rau 3-4 ntau yam ntawm lub tshuab ntau lawm tsis ua hauj lwm. , tus nqi ntawm cov khoom tiav yuav raug txo los ntawm tsawg kawg yog ib feem pua.

Aluminium extrusion cuab yeej muaj xws li: extrusion cylinder, extrusion pas nrig, extrusion ncoo, tuag ncoo, etc.Mainly los xyuas kom meej tias lub extrusion lub tog raj kheej, pas nrig, pwm peb concentric. Secondly, tsim nyog txij nkawm ntawm lub extrusion lub tog raj kheej, kom raug cua sov, los xyuas kom meej tias qhov kawg nto ntawm lub tog raj kheej yog du. Tshem tawm txhua yam ntawm extrusion lub tog raj kheej thiab tuag nrog qhov tshwm sim tsis zoo.Tshaj tawm cov seem ntawm txhuas nyob rau hauv cov phab ntsa sab hauv ntawm lub tog raj kheej extrusion tsis tu ncua, xyuas seb cov phab ntsa hauv lub qhov puas puas, siv cov ntaub ntawv tuag kom raug, thiab txhim kho kev txhawb zog ntawm cov tuag.

Extrusion kub, extrusion ceev thiab cua txias peb, nyob rau hauv cov khoom qauv, txhua yam khoom, nto zoo muaj feem xyuam rau qhov zoo, kuj yuav cuam tshuam rau yield.Nyob rau hauv tas li ntawd, peb yuav cuam tshuam rau qhov ntev ntawm cov khoom, lub casting pas nrig kub yog siab, Lub extrusion ceev ceev, qhov txias txias yog tsawg, yuav ua rau qhov ntev ntawm cov khoom tom qab extrusion nce, qhov kev loj hlob tuaj yeem nce mus txog 0.5% - 1%, kuj cuam tshuam rau linear ntom ntawm profile, yog li cov txheej txheem ruaj khov tuaj yeem txhim kho cov qoob loo.

Txhim kho cov txheej txheem extrusion tom ntej kom tsis txhob muaj kev pov tseg.Extruding cov txheej txheem tom ntej ntawm kev thauj mus los, feem ntau them nyiaj rau qhov profile ntawm khawb khawb.

Ib qho tuag ntxeem tau extrusion tuaj yeem txhim kho cov txiaj ntsig ntawm cov khoom tiav.

Rau qee cov khoom tsim nyog rau ntau qhov cua extrusion, kom deb li deb tau siv cov ntxeem tau extrusion, tsis tsuas yog tuaj yeem txo qhov extrusion coefficient, txo thiab siab, tab sis kuj tuaj yeem txhim kho cov txiaj ntsig.Raws li cov xwm txheej uas cov khoom pov tseg yog xoom, cov txiaj ntsig ntawm ob lub qhov extrusion tuaj yeem nce 3% ~ 4% dua li ntawm ib lub qhov extrusion.

Extrusion ceev yog cov txheej txheem tseem ceeb hauv cov txheej txheem extrusion, uas muaj feem xyuam rau qhov zoo ntawm cov khoom thiab ntau lawm efficiency.Extrusion ceev tsis zoo li los ua tus txheej txheem kub, ib hom alloy txheej txheem kev kho cua sov tuaj yeem xaiv qhov kub, thiab lub extrusion ceev yog ib tug heev empirical txheej txheem parameter.Different alloy profiles nrog txawv seem muaj txawv extrusion speeds.Tib yam khoom raug cuam tshuam los ntawm qhov kub thiab txias ntawm cov txheej txheem extrusion, thiab cov extrusion speeds txawv ua ntej thiab tom qab extrusion.Kom kom tswj tau qhov ceev ntawm extrusion, nws yuav tsum yog:

Kev txawj ntse thiab yoog raws qhov ntau ntawm extrusion ceev ntawm ntau yam alloys, ntau ntu (nrog rau phab ntsa tuab), thiab xyuam xim rau qhov cuam tshuam ntawm extrusion ceev ntawm aluminium profiles, xws li nto zoo, molding degree, thiab lwm yam.

Paub txog kev muaj peev xwm ntawm cov khoom siv extrusion los tswj extrusion ceev.Qee extruders muaj tas li extrusion tswj thiab PLC tswj, ib txhia tsuas muaj PLC tswj, thiab ib txhia tsis muaj.Thaum ib tug muab extrusion ceev, qee cov extruders tuaj yeem pib nias qhov ceev ntawm extrusion, Nrog rau kev txo qis ntawm cov billet nyob rau hauv lub extrusion cylinder, extrusion siab yog txo, lub outflow ceev ntawm cov khoom yuav sai thiab sai, tej zaum yuav ua rau cov khoom tom qab lub tawg.Yog li ntawd, nws yog tsim nyog los kho lub extrusion ceev.Tsuas yog los ntawm nkag siab txog lub xeev ntawm cov cuab yeej siv tau lub extrusion ceev yuav raug kho kom raug thiab tswj.

Nkag siab qhov cuam tshuam ntawm cov pwm sib txawv ntawm extrusion ceev. Feem ntau hais lus, lub extrusion ceev ntawm ca tuag (khoom profile) yog siab tshaj qhov uas ntawm split tuag (hollow profile).Tab sis tib yam pwm, tib seem zoo li cov khoom, vim hais tias ntawm cov qauv tsim thiab kev tsim cov qib sib txawv, qhov extrusion ceev yog txawv.Tshwj xeeb, cov seem muaj phab ntsa thickness sib txawv, los yog semi-hollow profile nrog qhib, uas muaj kev sib raug zoo nrog cov pwm.Tsuas yog qee qhov extrusion ceev tsim los ntawm pwm yog qhov zoo tshaj plaws.Qhov nrawm nrawm dhau los yog qeeb dhau, thiab nws yooj yim los tsim kev sib tw thiab qhib thiab kaw.

Txo cov khoom pov tseg los ntawm kev ntxiv dag zog rau kev tshuaj xyuas thawj zaug thiab kev tshuaj xyuas cov txheej txheem

Lub sab nrauv ntawm cov khoom siv khib nyiab, xws li phab ntsa tuab ntawm kev ua siab ntev, sib tw, dav hlau tshem tawm, qhib lossis kaw, thiab lwm yam, feem ntau yog nyob ntawm thawj tus pas nrig tom qab kev kuaj pwm los ntawm tus tswv tsev hauv kev kuaj xyuas thiab cov neeg soj ntsuam zoo. nyob rau hauv lub tensile tshuaj xyuas los tiv thaiv cov tiam ntawm xws li cov khoom pov tseg.Qhov dav dav phab ntsa thickness kam rau ua yuav tsum tau tswj los ntawm qhov tsis zoo kam rau ua, vim hais tias nrog cov nruam zus tau tej cov khoom, phab ntsa thickness ntawm cov khoom yuav maj mam thicker vim gradual hnav thiab tsim kua muag. ntawm cov pwm.Rau cov phab ntsa loj loj, thaum kos duab thiab ncaj nraim kom ua tib zoo xyuas cov duab kos, tswj tus nqi tsim nyog ntawm stretching.

Cov khib nyiab pov tseg xws li khawb, txiv kab ntxwv tev, cov ntaub so ntswg, cov pob dub, npuas, feem ntau tsis yog tag nrho cov hauv paus khoom tshwm sim.Nws yog ib qho tsim nyog los xyuas ib leeg los ntawm tus tswv tsev, tus neeg soj ntsuam zoo thiab cov txheej txheem sawing ntawm cov khoom tiav, thiab sib koom saib xyuas kev tshem tawm cov khoom pov tseg ntawm qhov chaw.

Yog tias tus neeg soj ntsuam zoo tsis pom muaj khawb ntawm lub rooj tawm, thiab pom cov khawb ntawm cov khoom tiav thaum sawing, nws yog ib qho tsim nyog yuav tsum tau xyuas los ntawm cov txheej txheem hloov dua siab tshiab ntawm lub txaj txias kom pom tias qee qhov ntawm txoj siv thauj khoom, khawb thiab lwm yam. yog tawv thiab tseem ceeb, ua rau khawb.

Kev tswj kom zoo yog kev tswj xyuas tag nrho cov neeg ua haujlwm thiab tag nrho cov txheej txheem.Txhua tus txheej txheem yuav tsum muaj qhov zoo, yog li kev tshuaj xyuas tus kheej, kev tshuaj ntsuam xyuas thiab kev tshuaj xyuas tshwj xeeb tuaj yeem ua ke, txhawm rau txhawm rau tshem tawm cov txheej txheem pov tseg hauv bud.Artificial tswj thiab txhim kho cov txiaj ntsig.

Los ntawm cov kev ntsuas saum toj no tuaj yeem txo cov geometric pov tseg, nws tuaj yeem pom tias qhov txo qis ntawm geometric pov tseg yog ib qho tseem ceeb ntawm kev tswj xyuas kev lag luam, uas muaj qhov tseem ceeb rau cov txiaj ntsig kev lag luam siab.

Txhawm rau txhim kho cov txiaj ntsig ntawm aluminium extrusion billet yog ua kom tiav thiab ua tib zoo ua cov txheej txheem ntawm extrusion ntau lawm, tsis yog tsuas yog cov txheej txheem yuav tsum nyob rau hauv qhov chaw, tab sis kuj cov kev tswj xyuas yuav tsum nyob rau hauv qhov chaw.Tseem muaj ntau chav rau Tuam Tshoj tus txhuas profile. kev lag luam los txhim kho cov txiaj ntsig, cov txiaj ntsig yuav yog cov txheej txheem tas mus li, txhim kho cov txiaj ntsig thiab txhim kho cov khoom lag luam zoo, cov khoom tsim tawm tau zoo sib xws.Is lub tuam txhab thev naus laus zis thiab kev tswj hwm qib ntawm cov khoom siv dav dav.

Txhim kho cov txiaj ntsig ntawm oxidized xim txhuas

Cov yield ntawm oxidation yog cov tawm los ntawm ib qho kev tsim khoom, uas yog, tawm los ntawm ib qho kev tsim tawm yam tsis muaj kev rov ua dua.Raws li kev xyaum ntau lawm, tus nqi ntawm reworked profiles yog 3 lub sij hawm ntawm cov uas tsis yog-reworked profiles, thiab nto zoo ntawm profiles tsis tau guaranteed.Tau kawg, qhov zoo ntawm oxidized khoom pib los ntawm lub rhiav casting.Vim muaj kev txwv qhov chaw, cov hauv qab no yog cov lus luv luv txog qee cov ntsiab lus uas yuav tsum tau them sai sai rau hauv cov txheej txheem oxidation ntau lawm.

Cov ntsia hlau nruab nrab ntawm tus pas nrig dai thiab cov kab hluav taws xob yuav tsum tau nruj me ntsis.Ua ntej khi cov khoom, peb yuav tsum xub xyuas seb lub hanging pas nrig yog tsau xoob.Yog hais tias nws yog me ntsis xoob, nws yuav tsum tau nruj me ntsis nyob rau hauv lub sij hawm.Lwm corrosion, dai pas nrig yuav ua me me, yuav tsum tau hloov nyob rau hauv lub sij hawm, vim hais tias nws conductive cheeb tsam yog me me, yooj yim los ua cua sov, tib lub sij hawm los khi, tiv thaiv cov profile poob rau hauv lub qhov uas tshwm sim los ntawm tus ncej, luv luv Circuit Court puas rau lub hwj chim mov.

Nyob rau tib lub sij hawm poob rau hauv lub profile ntawm lub tank yuav tsum tau muab ntxuav tawm nyob rau hauv lub sij hawm, xws li alkali ntxuav tank rau hauv ib tug profile, nws yuav sai sai corrosion, qhov kev sim ua pov thawj tias alkali noj yog sib npaug rau alkali ntxuav ntawm 50-100. hauv paus ntawm cov profile ntawm cov alkali noj.Poob rau hauv cov xim tank los yog sealing tank, vim corrosion, lub tank yuav sau ib tug loj tus naj npawb ntawm txhuas ions, cuam tshuam rau lub neej kev pab cuam ntawm lub tank kua.

Kev khi cov khoom siv nrog txhuas hlau nrog ob hom kev qhia tshwj xeeb yog qhov zoo, aniseed xaiv coarse txhuas hlau, cov khoom nruab nrab thiab cov khoom me me yog siv rau hauv cov hlau zoo txhuas, siv tau 2 hli thiab 3 hli, los yog 2.2 hli thiab 3.2 hli ob hom specifications, txhuas hlau annealing hardness yuav siv sij hawm 1/2 ~ 3/4 yog zoo.Tam sim no, ntau lub lag luam tau hloov dua siab tshiab rau jig.

Ua ntej dai rau hauv lub tank oxidation kom nruj txhua qhov profile; Cov khoom siv rov ua dua ua ntej oxidation ntawm cov khoom siv, siv cov pliers los tuav qhov kawg ntawm qhov profile kom nws hloov ua ntej cov khoom, kom cov kev sib cuag tsis muaj zaj duab xis, kom ntseeg tau zoo conductivity .

Cov khoom siv dai rau hauv lub tank oxidation thiab xim tank conductive lub rooj yuav tsum tau them sai sai rau txoj cai, txwv tsis pub nws yog qhov sib txawv ntawm Yin thiab Yang complexion.

Tom qab qhov kawg ntawm lub zog oxidation raug tshem tawm hauv lub sijhawm, nyob hauv lub tank oxidation rau ob peb feeb yuav cuam tshuam rau lub qhov sib khi, tseem yuav ua rau cov xim nrawm nrawm; Tom qab oxidation, nws yog lifted thiab qaij nyob rau hauv cov huab cua ntev dhau lawm.Ib qho kawg ntawm cov kua qaub txo cov kua qaub yog darkened vim qhov pore expansion ntawm oxide zaj duab xis, thiab xim txawv ntawm ob qho tag nrho yog ib qho yooj yim mus tshwm.

Tus nqi pH ntawm plaub lub taub dej ntxhua ua ntej thiab tom qab lub tank xim yuav tsum tau khaws cia kom ruaj khov.Tus nqi pH ntawm plaub lub taub dej ntxhua khaub ncaws yog tswj raws li hauv qab no:

Tus nqi pH ntawm thawj da dej tom qab oxidation: 0.8 ~ 1.5

Tus nqi pH ntawm lub da dej thib ob tom qab oxidation: 2.5 ~ 3.5

Tus nqi pH ntawm thawj da dej tom qab xim: 1.5 ~ 2.5

Tus nqi pH ntawm lub tank thib ob tom qab xim: 3.5 ~ 5.0

Raws li qhov xwm txheej ib txwm muaj, qee qhov dej ntws tawm tau qhib thaum lub sijhawm tsim khoom, thiab lub valve nkag tau raug kaw thaum lub sijhawm tsim khoom.Nws yuav tsum tsis txhob ntws los yog ntxiv dej rau hauv tag nrho lub tank.Yog tias cov dej nyob twj ywm hauv thawj lub tank tom qab oxidation rau ob peb feeb, cov xim yuav nrawm dua, thiab yog tias cov dej nyob twj ywm hauv lub tank thib ob, cov xim yuav qeeb.

Rau kev tsim cov khoom siv xim xim imitation steel, txoj kev xim feem ntau tau txais ua ntej, tom qab ntawd rov qab mus rau cov qauv xim phaj.Vim cov xim sib txawv ntawm cov xim hlau xim lub sij hawm tswj ntau yam me me (tsuas yog 2 ~ 3 vib nas this) , thiab siv txoj cai fading tuaj yeem muaj 10 ~ 15 vib nas this ntawm lub sijhawm tswj xim, thiab kev sib koom ua ke fading kuj yog qhov tsim nyog rau tib xim tom qab, rau cov imitation steel fading thiab cov xim ntxiv yog xim zoo li tig ntsuab, thiab xim ib zaug yuav nyiam. ua liab.

Hom khoom dai ntawm lub tank xim thiab thawj lub tank ntxuav tom qab xim tom qab dai tsis txhob tso tseg lub sij hawm khoob yog ntev dhau lawm, txwv tsis pub cov profile nto yuav tshwm ribbon, xim tsis sib xws thiab cov kua dej kawg ntawm qhov tshwm sim dawb, yuav tsum yog me ntsis ntawm cov xim ntawm Tom ntej no ntxuav nyob rau hauv lub sij hawm, qhov tseeb xim yuav tsum yog nyob rau hauv lub thib ob ntxuav tom qab. Feem ntau hais lus, rau imitation steel cov ntaub ntawv, xws li sib piv template xim liab, nws qhia tau hais tias lub sij hawm colouring tsis txaus rau ntxiv cov xim; Yog hais tias cov xim yog daj. , nws tau ua xim, raws li xim qhov tob, koj tuaj yeem xaiv rov qab rau hauv lub tank xim lossis hauv thawj lub tank ntxhua tom qab xim.

Ntxiv txoj kev ntawm cov tshuaj nyob rau hauv lub colouring tank: stannous sulfate thiab npib tsib xee sulfate yuav tsum tau yaj nyob rau hauv lub tank, thiab cov xim additive yuav tsum tau yaj nyob rau hauv cov dej ntshiab (cov dej ntshiab yog soluble).Nws yuav tsum raug sau tseg tias cov khoom siv ntxiv tuaj yeem nchuav tom qab yaj tag, thiab cov concentrated sulfuric acid tuaj yeem raug nchuav ncaj qha rau hauv lub tank xim.

Qhov kub, sijhawm thiab dej zoo ntawm cov dej kub ntxuav ua ntej electrophoresis yuav tsum tau lav.Yog tias qhov seem SO42- nyob rau hauv lub qhov oxide zaj duab xis tsis tau ntxuav, yellowing thiab opacity ntawm cov xim zaj duab xis yuav tshwm sim tom qab electrophoresis thiab ci.Raws li cov xwm txheej, cov dej kub kub tswj ntawm 60 ~ 70 ℃, thiab cov dej kub ntxuav. lub sijhawm yog 5 ~ 10 feeb.

Post lub sij hawm: Mar-26-2021