Kev siv cov txhuas extrusion hauv cov khoom tsim thiab kev tsim khoom tau nce ntau nyob rau xyoo kaum xyoo tsis ntev los no.

Raws li tsab ntawv ceeb toom tsis ntev los no los ntawmTechnavio, ntawm 2019-2023 qhov kev loj hlob ntawm lub ntiaj teb aluminium extrusion kev lag luam yuav nrawm nrog tus Compound Annual Growth Rate (CAGR) ntawm yuav luag 4%.

Tej zaum koj tau hnov txog cov txheej txheem tsim khoom no thiab xav paub tias nws yog dab tsi thiab nws ua haujlwm li cas.

Aluminium Extrusion yog dab tsi?

Aluminium extrusion yog txheej txheem los ntawm cov khoom siv aluminium alloy raug yuam los ntawm kev tuag nrog rau qhov tshwj xeeb hla ntu profile.

Aluminium extrusion tuaj yeem ua tau zoo li cov tshuaj txhuam hniav los ntawm ib lub raj.Ib lub zog ram thawb cov txhuas los ntawm qhov tuag thiab nws tawm ntawm qhov qhib tuag.Thaum nws ua, nws tawm hauv tib lub cev raws li qhov tuag thiab raug rub tawm raws li kev khiav tawm. table.Ntawm theem tseem ceeb, cov txheej txheem ntawm aluminium extrusion yog yooj yim to taub.

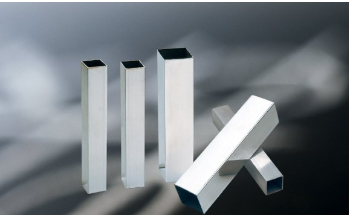

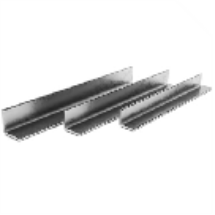

Nyob rau sab saum toj yog cov duab kos siv los tsim cov tuag thiab hauv qab yog renderings ntawm qhov tiav aluminium profiles yuav zoo li.

Cov duab peb pom saum toj no yog txhua yam yooj yim, tab sis cov txheej txheem extrusion kuj tso cai rau kev tsim cov duab uas muaj ntau qhov nyuaj.

Muaj pes tsawgTxheej txheem?

Cia peb saib hauv qab Aluminium Art.Nws tsis yog tsuas yog pleev xim zoo nkauj xwb, uas suav nrog ntau cov kauj ruam ntawm txhuas extrusion.

1):Lub Extrusion Tuag yog npaj thiab txav mus rau Extrusion Xovxwm

Ua ntej, ib puag ncig-shaped tuag yog machined los ntawm H13 steel.Los yog, yog tias ib qho twb muaj lawm, nws raug rub los ntawm lub tsev khaws khoom zoo li qhov koj pom ntawm no.

Ua ntej extrusion, tuag yuav tsum tau preheated rau ntawm 450-500 degrees celsius los pab txhawb nws lub neej thiab xyuas kom meej txawm hlau ntws.

Thaum cov tuag tau preheated, nws tuaj yeem thauj mus rau hauv cov xovxwm extrusion.

2):Aluminium Billet yog Preheated Ua ntej Extrusion

Tom ntej no, ib qho khoom, cylindrical thaiv ntawm aluminium alloy, hu ua billet, yog txiav los ntawm lub cav ntev ntawm cov khoom siv hlau.

Nws yog preheated nyob rau hauv ib lub qhov cub, zoo li qhov no, rau ntawm 400-500 degrees celsius.

Qhov no ua rau nws malleable txaus rau cov txheej txheem extrusion tab sis tsis molten.

3) Lub Billet raug xa mus rau Extrusion Xovxwm

Thaum lub billet tau preheated, nws yog pauv mus rau mechanically rau lub extrusion xovxwm.

Ua ntej nws thauj mus rau hauv xovxwm, ib lub roj nplua nyeem (lossis tso tawm tus neeg sawv cev) yog siv rau nws.

Tus neeg sawv cev tso tawm kuj tau siv rau lub extrusion ram, los tiv thaiv lub billet thiab ram los ntawm kev ua ke.

4)Lub Ram thawb cov khoom Billet rau hauv lub thawv

Tam sim no, lub malleable billet yog loaded rau hauv extrusion xovxwm, qhov twg hydraulic ram siv txog li 15,000 tons ntawm siab rau nws.

Raws li tus ram siv siab, cov khoom siv billet raug thawb rau hauv lub thawv ntawm cov xovxwm extrusion.

Cov ntaub ntawv nthuav dav kom sau cov phab ntsa ntawm lub thawv

5)Cov khoom Extruded Emerges Los ntawm Tuag

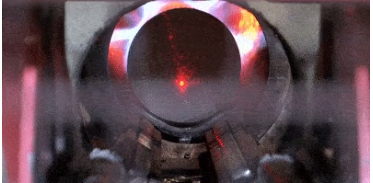

Raws li cov khoom siv alloy ntim rau hauv lub thawv, nws tam sim no tau raug nias tawm tsam extrusion tuag.

Nrog rau kev siv txuas ntxiv mus rau nws, cov khoom siv txhuas tsis muaj qhov twg los tsuas yog tawm ntawm qhov qhib (s) hauv qhov tuag.

Nws tshwm sim los ntawm qhov tuag qhov qhib nyob rau hauv cov duab ntawm ib tug tag nrho-tsim profile.

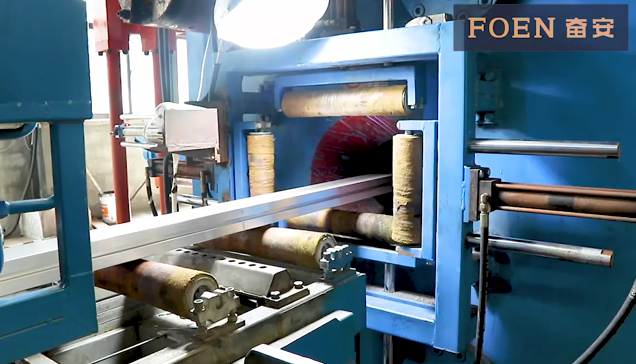

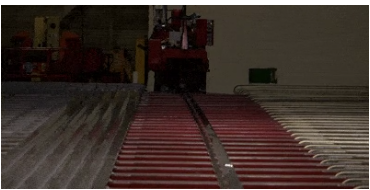

6)Extrusion yog coj raws li lub rooj Runout thiab quenched

Tom qab tshwm sim, lub extrusion yog tuav los ntawm ib tug ruber, zoo li ib tug koj pom ntawm no, uas coj nws raws lub runout rooj ntawm ib tug ceev uas phim nws tawm ntawm lub xovxwm.Raws li nws txav raws lub runout rooj, lub profile yog "quenched, ” los yog ib txwm txias los ntawm da dej los yog los ntawm cov kiv cua saum rooj.

7)Extrusion yog sheared rau lub rooj Length

Thaum lub extrusion ncav cuag nws lub rooj ntev, nws yog sheared los ntawm ib tug kub saw kom cais nws los ntawm extrusion txheej txheem.

Hauv txhua kauj ruam ntawm cov txheej txheem, qhov kub thiab txias plays lub luag haujlwm tseem ceeb.

Txawm hais tias lub extrusion tau quenched tom qab tawm hauv xovxwm, nws tseem tsis tau tag nrho txias.

8)Extrusion yog txias rau chav kub

Tom qab shearing, lub rooj-ntev extrusion yog mechanically pauv los ntawm lub rooj runout mus rau lub rooj txias, zoo li qhov koj pom ntawm no.Cov profiles yuav nyob twj ywm nyob rau ntawd kom txog thaum lawv ncav cuag chav tsev kub.

Thaum lawv ua, lawv yuav tsum tau ncab.

Extrusion yog txias rau chav kub

Tom qab shearing, lub rooj ntev extrusion yog mechanically hloov ntawm lub rooj runout mus rau lub rooj txias, zoo li qhov koj pom ntawm no.

Cov profiles yuav nyob ntawd kom txog thaum lawv ncav cuag chav sov.

Thaum lawv ua, lawv yuav tsum tau ncab.

9)Extrusion yog txav mus rau Stretcher thiab Stretched rau hauv Alignment

Qee qhov kev sib tw ntuj tau tshwm sim nyob rau hauv cov profiles thiab qhov no yuav tsum tau kho. Kom kho qhov no, lawv raug tsiv mus rau ib tug stretcher.Txhua qhov profile yog mechanically tuav ntawm ob qho tag nrho thiab rub kom txog thaum nws ncaj ncaj thiab tau coj mus rau hauv cov lus qhia.

10)Extrusion yog txav mus rau qhov kawg pom thiab txiav rau ntev

Nrog rau lub rooj ntev extrusion tam sim no ncaj thiab tag nrho ua hauj lwm-hardened, lawv raug xa mus rau lub rooj saw.

Ntawm no, lawv tau saws rau qhov ntev ntev, feem ntau ntawm 8 thiab 21 feet ntev.Lub sijhawm no, cov khoom ntawm cov extrusion sib phim lub npau taws.

Dab tsi tshwm sim tom ntej?

Surface Finishing: Txhim kho qhov tshwm sim thiab kev tiv thaiv corrosion

Ob lub laj thawj tseem ceeb los xav txog cov no yog tias lawv tuaj yeem txhim kho cov tsos ntawm aluminium thiab tuaj yeem txhim kho nws cov khoom corrosion.Tab sis muaj lwm yam txiaj ntsig thiab.

Piv txwv li, cov txheej txheem ntawm anodization thickens cov hlau ib txwm ua oxide txheej, txhim kho nws cov corrosion kuj thiab kuj ua rau cov hlau ntau resistant rau hnav, txhim kho deg emissivity, thiab muab ib tug ntxeem tau nto uas tuaj yeem txais cov xim sib txawv.

Lwm cov txheej txheem tiav xws li kev pleev xim, hmoov txheej, xuab zeb blasting, thiab sublimation (los tsim cov ntoo zoo), tuaj yeem ua tiav thiab.

Aluminium extrusion yog txheej txheem los tsim qhov chaw nrog cov ntu ntu ntu profile los ntawm kev thawb cov khoom siv hlau los ntawm kev tuag.Nws yog txheej txheem tsim khoom tseem ceeb.

Post lub sij hawm: May-10-2021