Nyob rau hauv nruab nrab-19th caug xyoo Fabkis, smelting aluminium technology yog li rov qab hais tias princes thiab cov nom tswv tsuas yog siv nyiaj cutlery ntawm banquets.Tsuas yog Napoleon II siv txhuas lub tais. Nrog rau daim ntawv thov ntawm electrolytic aluminium technology, txhuas ntau thiab ntau dua rau hauv pej xeem lub neej; Nrog rau kev txhim kho cov txheej txheem kho deg ntawm aluminium alloy, aluminium hlau nrog cov tswv yim zoo muaj txiaj ntsig zoo nkauj.Kuv tau teev 6 cov kev kho mob ntawm txhuas nto.Koj paub dab tsi ntxiv?

Cov khoom siv hlau siv ntau dua thiab ntau dua ntawm cov khoom siv uas twb muaj lawm, vim tias cov khoom siv hlau ntau tuaj yeem cuam tshuam cov khoom zoo, qhia txog tus nqi ntawm cov khoom siv, thiab hauv ntau cov khoom siv hlau, aluminium vim nws yooj yim ua, pom kev zoo, kev kho deg. Txoj kev yog nplua nuj, thawj zaug tau txais los ntawm txhua lub chaw tsim khoom, kev kho mob ntawm aluminium feem ntau yog muab faib ua: xuab zeb blasting (los tsim cov matte pearl nyiaj tiav), polishing (los tsim daim iav tiav), hlau kos duab (los tsim satin tiav) , electroplating (kom npog lwm yam hlau), thiab tshuaj tsuag (kom npog lwm yam nonmetallic coatings).

Cia peb saib cov txheej txheem txheej txheem txheej txheem ntawm aluminium thiab aluminium alloy hauv peb cov khoom siv niaj hnub.

Sandblast

Cov txheej txheem ntawm kev ntxuav thiab coarsening hlau qhov chaw los ntawm kev cuam tshuam ntawm kev kub ceev xuab zeb ntws.Qhov no txoj kev kho deg ntawm txhuas qhov chaw tuaj yeem ua rau saum npoo ntawm lub workpiece kom tau txais qee qhov kev huv huv thiab qhov sib txawv roughness, yog li cov khoom siv ntawm cov khoom siv. nto ntawm lub workpiece yog txhim kho, thiaj li los txhim kho qhov qaug zog tsis kam ntawm workpiece, nce adhesion ntawm nws thiab txheej, ncua lub durability ntawm txheej zaj duab xis, tab sis kuj conducive rau cov xim txaus thiab kho kom zoo nkauj.Cov txheej txheem no feem ntau pom. nyob rau hauv ntau yam Apple cov khoom, thiab yog nce siv nyob rau hauv uas twb muaj lawm rooj plaub TV los yog nruab nrab ntas.

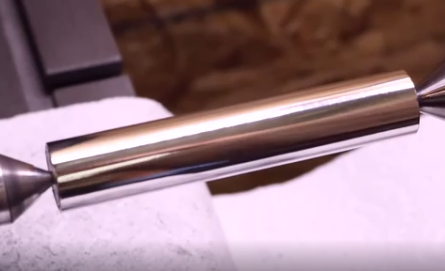

Polishing

Cov txheej txheem uas qhov roughness ntawm lub workpiece raug txo los ntawm txhua yam, tshuaj los yog electrochemical txhais tau tias kom tau ib tug kaj, tiaj tus nto.Polishing txheej txheem mas muab faib mus rau hauv: mechanical polishing, tshuaj polishing, electropolishing.Aluminium qhov chaw siv mechanical polishing + electrolytic polishing tuaj yeem nyob ze rau cov nyhuv stainless hlau daim iav, muab rau tus neeg uas muaj qib siab yooj yim, kev xav zoo rau yav tom ntej (ntawm chav kawm yooj yim tawm cov ntiv tes tab sis kuj muaj kev saib xyuas ntau dua)

Hlau kos duab

Hlau daim duab yog cov txheej txheem tsim khoom ntawm kev rov ua dua ib daim ntawv txhuas tawm ntawm cov xaim nrog cov ntawv xuab zeb. Hlau kos duab tuaj yeem muab faib ua cov duab kos ncaj nraim, random hlau kos duab, muab kauv hlau kos duab, xov kos duab. Hlau hlau kos duab txheej txheem, tuaj yeem qhia meej txhua qhov me me. txhob lo lo ntxhuav cim, thiaj li hais tias cov hlau matte nyob rau hauv kev sib kis ntawm cov plaub hau zoo luster, cov khoom muaj ib tug nkag siab ntawm zam thiab science thiab technology.

Highlights qhov txiav

Lub pob zeb diamond cutter yog ntxiv dag zog los ntawm lub tshuab engraving nyob rau hauv kev kub ceev kev sib hloov (kev ceev ceev yog 20000 RPM) ntawm lub tshuab engraving spindle rau txiav qhov chaw, uas ua rau hauv cheeb tsam highlighting cheeb tsam ntawm qhov chaw ntawm cov khoom.Qhov ci ntsa iab ntawm cov txiav highlight yog cuam tshuam. los ntawm qhov ceev ntawm milling me ntsis.Qhov ceev me ntsis ceev yog, qhov ci ntsa iab ntawm qhov txiav qhov tseem ceeb yuav yog, thaum lub vice versa.

High-gloss high-gloss txiav yog tshwj xeeb tshaj yog siv hauv cov xov tooj ntawm tes, xws li iPhone5.Nyob rau hauv xyoo tas los no, qee qhov high-end TV teeb tau txais cov txheej txheem high-gloss milling rau cov hlau ncej.Tsis tas li ntawd, cov txheej txheem anodic oxidation thiab hlau kos duab ua rau TV tag nrho ntawm kev zam thiab kev nkag siab ntawm kev tshawb fawb thiab thev naus laus zis.

Anodic oxidation

Anodic oxidation yog hais txog electrochemical oxidation ntawm hlau los yog hlau alloy, txhuas thiab nws cov alloy nyob rau hauv cov electrolyte thiab tej txheej txheem tej yam kev mob, vim qhov kev txiav txim ntawm sab nraud tam sim no, nyob rau hauv tus txheej txheem ntawm tsim ib txheej ntawm oxide zaj duab xis ntawm cov khoom txhuas (anode) .Anodic oxidation tuaj yeem tsis tsuas yog daws tau cov aluminium nto hardness, hnav tsis kam thiab lwm yam ntawm qhov tsis xws luag, tab sis kuj tuaj yeem txuas ntxiv lub neej kev pab cuam ntawm txhuas thiab txhim khu kev zoo nkauj, tau dhau los ua ib qho tseem ceeb ntawm kev kho aluminium nto, yog qhov dav tshaj plaws. siv thiab ua tau zoo heev.

Ob-xim anodizing

Ob-xim anodizing yog hais txog anodizing ib yam khoom thiab muab ib cheeb tsam ib qho xim sib txawv.Tus nqi ntawm ob-xim anodic oxidation yog siab vim yog cov txheej txheem nyuaj.Tab sis los ntawm qhov sib txawv ntawm ob.

Post lub sij hawm: Jul-03-2021